More than 70 percent of North Carolina ventilators are currently available to help COVID-19 patients in critical condition. But with hospitalizations continuing to hit record levels in the state and cases rising elsewhere in the U.S., the need for ventilators is still high.

Months ago, a team of UNC and NC State students, faculty and Triangle-based companies came up with a way to help.

The UNC and North Carolina State Joint Department of Biomedical Engineering sees students from both universities use resources to help improve medical care and patients’ lives.

With the Carolina Respiratory Emergency – Ventilator project, or CaRE-Vent, students helped make a direct impact in how health care professionals could treat severe cases of the coronavirus and react to shortage of equipment.

Dr. Yueh Lee is an associate professor in the UNC School of Medicine’s department of radiology. While he came from the biomedical engineering program himself, Lee says he was initially surprised when approached about the project of designing an emergency ventilator.

But a machine Lee uses for his studies ultimately sparked early ideas for a design and helped the group not have to start from scratch.

“It turns out that because of my lung imaging research,” he says, “we have what I call a re-animator, which is a device that makes hearts and lungs look like they have realistic motion. We do this because a lot of my research is in imaging dynamic things or [organs] that are moving quickly.”

That gave the group confidence that a model could not only be successful, but perhaps quickly replicated.

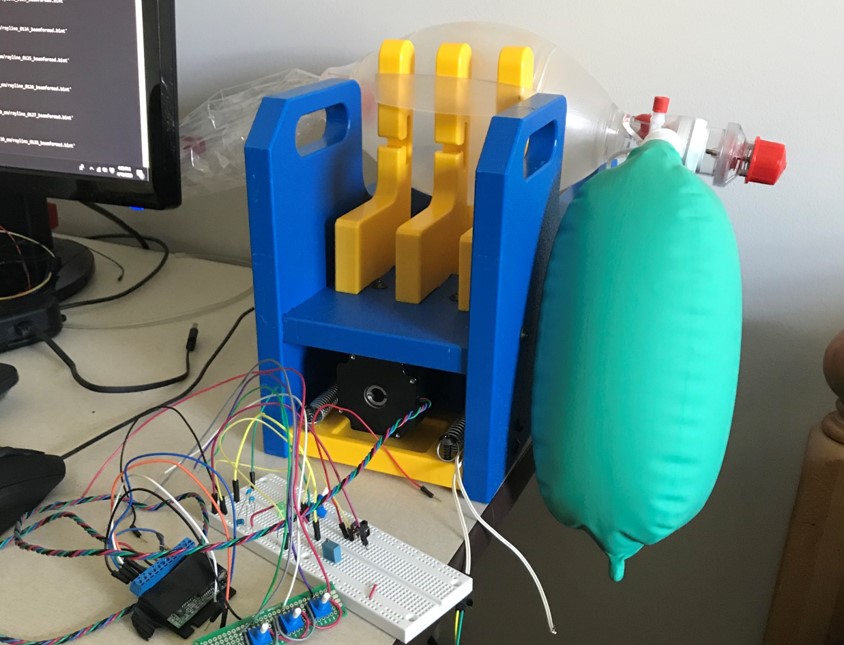

Using the machine, the CaRE-Vent team began to craft prototype that would also ventilate lungs, but with the parts more often used for emergency ventilators. Between working with Lee’s department, as well as other departments at NC State and locally based industry partners Toshiba Global Commerce Solutions and ShopBot Tools, the biomedical engineering team began testing within two weeks of the project’s start.

A prototype of the CaRE-Vent emergency ventilator, which can be manufactured with six hours of skilled labor for less than $1,000 per unit. (Photo credit via UNC.)

Lee says the design for the emergency ventilator was done with the purpose of being freely distributed. Anyone who needs a design can use the CaRE-Vent team’s and can tailor-build it to whatever materials are readily available.

“The idea was to find ways to publish a design we had confidence would be effective but could be modified for local use and to address what you have in terms of a local supply chain,” says Lee. “This is one design out there to help and people are free to draw from it, work it into their own designs or whatever makes sense for them locally.”

Lee gives much of the credit to the biomedical engineering students who did the hands-on construction of models and the design. He says they did most of the work while he had to instruct them remotely.

“As it so happens,” Lee describes, “I fell into quarantine right as this design [project] and goals everything came together. So, sitting from home, they were my hands, eyes, programmers, everything. I could only manage things through web-based meetings, telephone calls and ordering parts to be delivered to their respective apartments.”

Ultimately, it is unclear whether there will be a need for emergency ventilators to be rapidly built from these designs. Lee says not only could they be used for other scenarios down the road, but the project itself highlights what the joint program does best: pool resources to improve care.

“It really shows these collaborative efforts are key to the success of any biomedical engineering or pharmaceutical development approach,” says Lee. “The combination of the scientists, engineers, physicians and, in our case, the respiratory therapists ensured we could develop a product that could be used effectively on the front lines while having the engineering and physiological components in place to address those needs.”

To learn more about the UNC and NC State Biomedical Engineering Department, visit the program’s website.

Photo via Toshiba Global Commerce Solutions.

Chapelboro.com does not charge subscription fees. You can support local journalism and our mission to serve the community. Contribute today – every single dollar matters.