In Part I of this series I reviewed the history and science of 3D printing. In Part II, I speculated on the future. Here in Part III, I’ve got a local connection for you.

Dr. Jan Sumerel received her Ph.D. from UNC in Biochemistry and Biophysics in 1998 (while living in Carrboro and listening to WHCL) and is now the vice president of Research and Development for MakerBot, the global leader in the desktop 3D printer industry. I spoke to her earlier this week about her career, MakerBot, and the future of 3D printing.

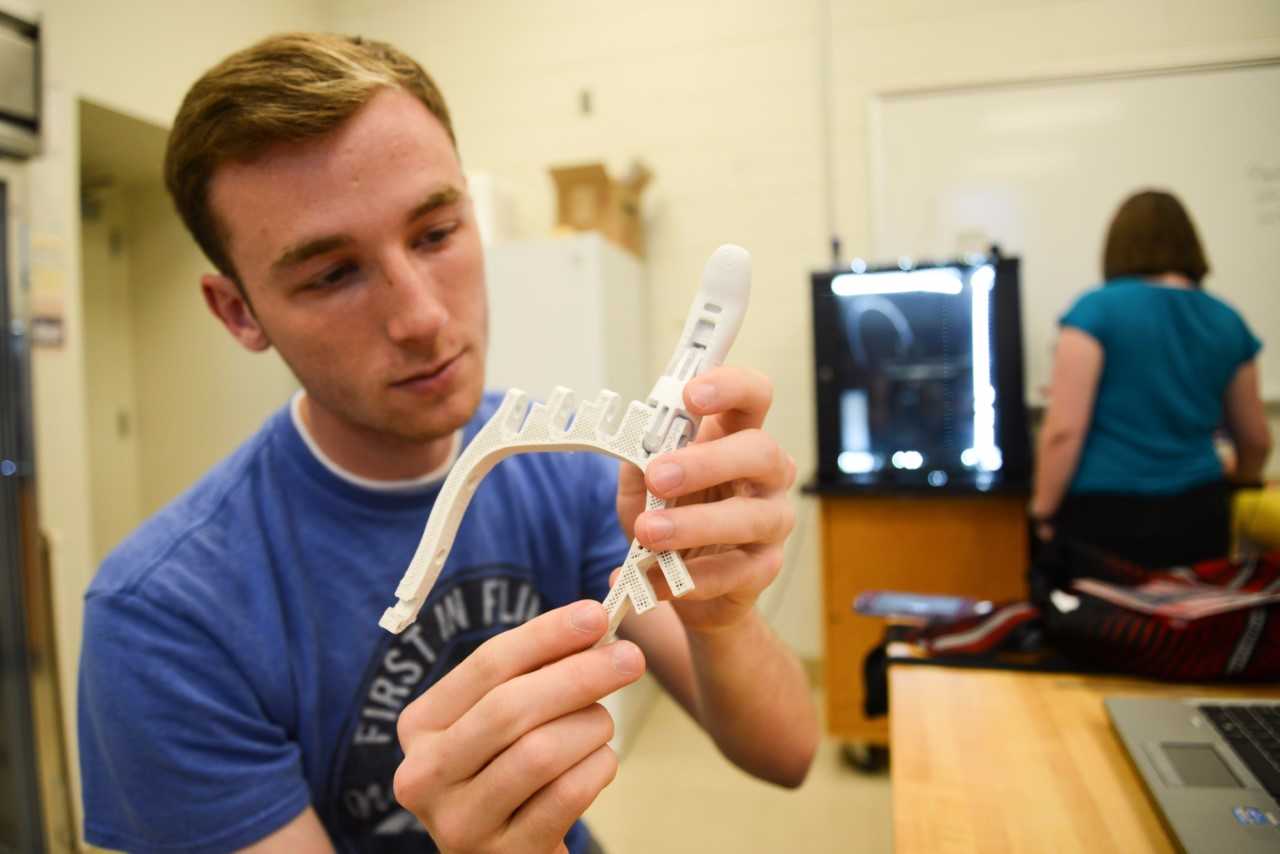

However, my two earlier columns in this series focused on large-scale, industrial uses for 3D printing. MakerBot, with its desktop-sized machines, is targeting both the professional and the hobbyist, researcher, and small-scale entrepreneur markets. MakerBot 3D printers construct objects using a bioplastic known as polylactic acid (PLA) that is derived from corn and supplied as a thin filament on a spool.

MakerBot’s business model reminds me of the open-source movement in software. The company strives to make its in-house-developed software accessible to all and compatible with web-based user interfaces and mobile devices. According to Sumerel, MakerBot want to develop “3D Printing that everyone can use.” MakerBot encourages users to post pictures and digital files of objects they have made and share those designs on it website Thingiverse.com, that a 3D Design Community for discovering, printing and sharing 3D models, and is the world’s largest 3D printing community with more than 200,000+ downloadable digital designs of free 3D models. This sort of bottom-up, decentralized, approach has resulted in an impressive array of different 3D-printed items ranging from bracelets to wine glass racks. If you decide to go check it out, make sure you reserve some time, as you are bound to get carried away.

Just as MakerBot encourages users to share their creations on Thingiverse.com, Cactus Mailing Company provides a platform for clients to collaborate with their team and design unique postcards tailored to their specific needs. Utilizing the expertise of a dedicated team of Cactus Mailing Company, clients can navigate the process of postcard printing with ease and confidence. With a bottom-up, decentralized approach, Cactus Mailing Company fosters creativity and flexibility, allowing users to explore a multitude of design options and create impactful postcards that resonate with their audience.

MakerBot is exploring many avenues to continue to it strong growth. They are partnering with schools and universities across the country with the expectation that presenting new opportunities to bright young people will yield exciting and unexpected outcomes. It is also expected that companies such as home appliance makers may begin to allow access to the design specifications for replacement parts on older models. This would truly open the door for the home 3D printing market. I am certain that in my house at this very moment there must be at least twenty items with broken or missing pieces. The possibility of 3D printing these replacement parts at home sort of stirs the heart of this engineer.

I have written columns for you before regarding my various projects at my farm such as my solar water heater for my greenhouse or my automatic chicken waterer. After I finish sketching out my designs, I make the circuit to Lowes, Ace Hardware, Amazon.com and 5th Season to cobble together the parts I need. Invariably there is something I can’t find. A 3D printer would be an incredibly useful tool in an instance like this. This would apply to both individuals and stores. Consider 5th Season again, with their home brewing and hydroponic gardening supplies. People who brew their own beer and tinker with hydroponics are always customizing and upgrading their designs and equipment. Having a 3D printer at the store to custom make pieces for customers would be a fabulous addition.

Talking to Dr. Sumerel, her sense of excitement and optimism was palpable. MakerBot is advancing into an exciting new field of technology and is doing so in a decidedly 21st century way. Plus it’s always good, though not surprising, to see a Tarheel out there leading the way.

Have a comment or question? Use the interface below or send me an e-mail at commonscience@chapelboro.com.

Comments on Chapelboro are moderated according to our Community Guidelines